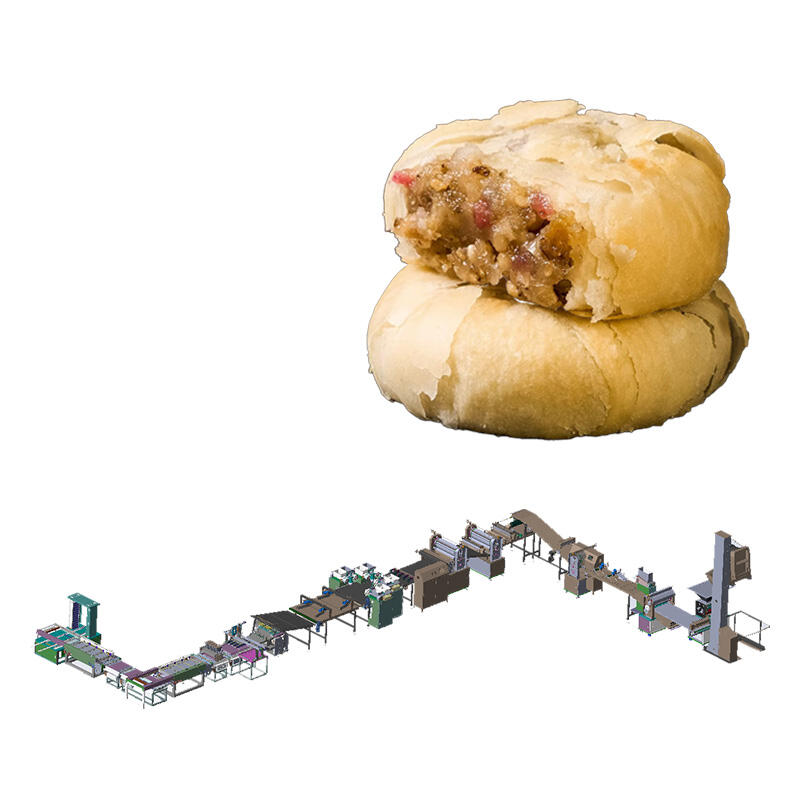

bakery maker machine

The bakery maker machine represents a revolutionary advancement in commercial and industrial baking technology, combining precision engineering with user-friendly operations. This versatile equipment streamlines the entire baking process, from mixing ingredients to producing perfectly baked goods. At its core, the machine features a powerful mixing system with variable speed controls, allowing for optimal dough development and consistency. The integrated temperature control system maintains ideal conditions throughout the baking process, ensuring consistent results every time. Advanced digital controls enable users to program and store multiple recipes, while the smart timing system automates the entire baking cycle. The machine's robust construction includes food-grade stainless steel components, ensuring durability and compliance with hygiene standards. Its modular design accommodates various attachments for different baking needs, from bread and pastries to cookies and cakes. The innovative moisture control system creates the perfect environment for proper crust formation and texture development. Safety features include emergency stop buttons, overheating protection, and automatic shutdown mechanisms. The machine's energy-efficient design reduces operational costs while maintaining high productivity levels, making it an ideal choice for bakeries of all sizes.