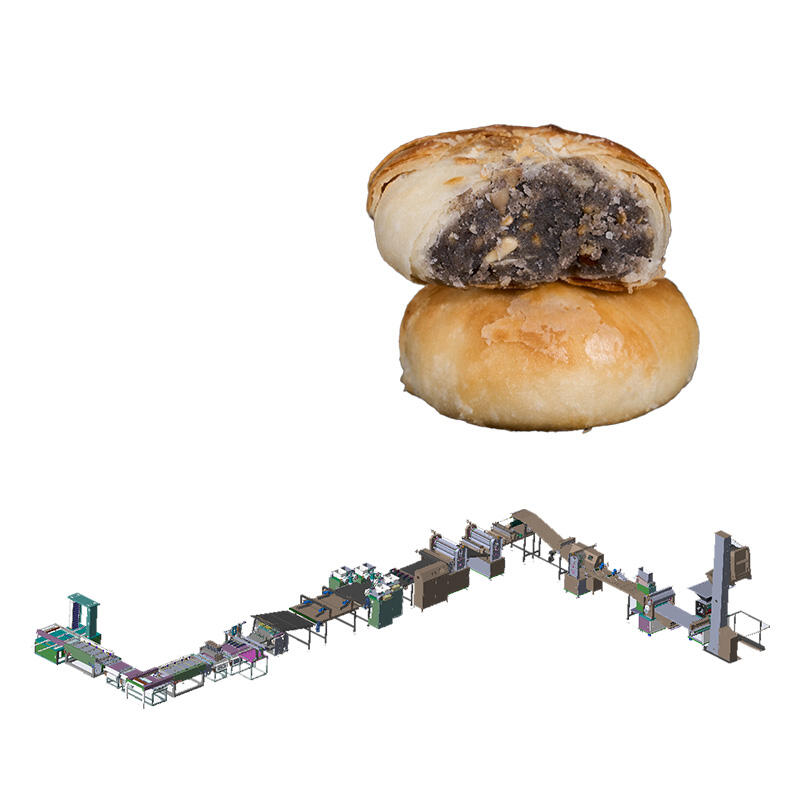

cookie dough cutter machine

The cookie dough cutter machine represents a revolutionary advancement in commercial baking equipment, designed to streamline the cookie production process with precision and efficiency. This sophisticated piece of equipment combines cutting-edge technology with practical functionality to transform bulk cookie dough into perfectly portioned pieces ready for baking. The machine features an automated feeding system that carefully handles the dough, maintaining its integrity while guiding it through specially designed cutting mechanisms. Advanced pressure control systems ensure consistent dough density, while adjustable cutting plates accommodate various cookie sizes and shapes. The machine's stainless steel construction guarantees food safety and durability, while its user-friendly interface allows operators to easily adjust settings for different dough types and production requirements. Built-in safety features protect operators during operation, and the machine's efficient design minimizes waste while maximizing output. Modern cookie dough cutters also incorporate smart technology for production monitoring and maintenance scheduling, ensuring optimal performance and reducing downtime. The machine's versatility extends to handling different dough consistencies, from soft to firm, making it suitable for a wide range of cookie varieties. With production capabilities ranging from small batch operations to high-volume industrial requirements, these machines have become essential equipment in bakeries of all sizes.