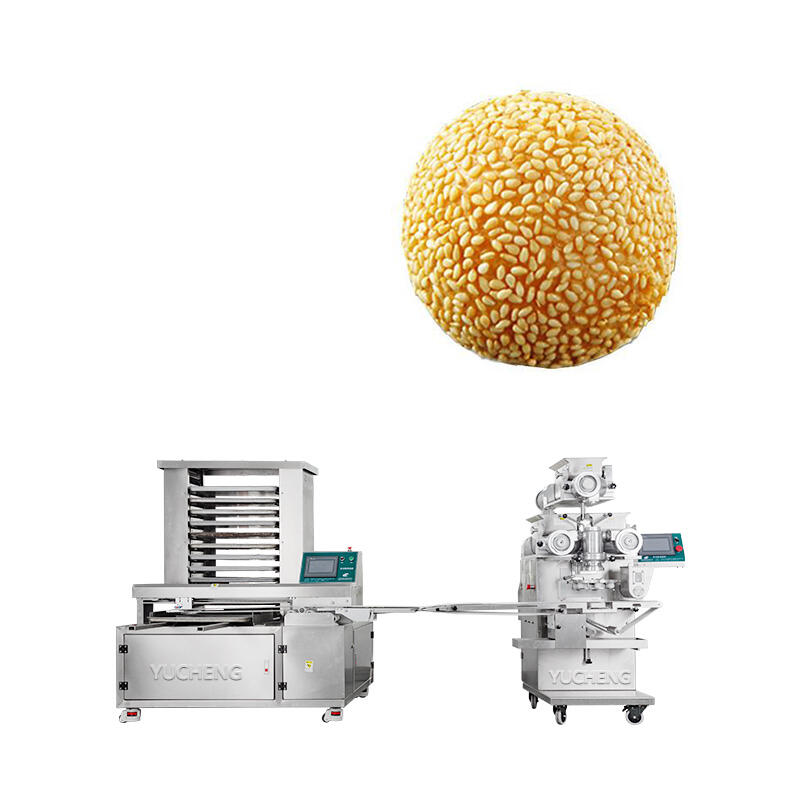

meatball processing machine

The meatball processing machine represents a revolutionary advancement in food processing technology, designed to streamline and automate the production of uniform, high-quality meatballs. This sophisticated equipment combines precision engineering with user-friendly operations to transform raw meat mixtures into perfectly formed meatballs with consistent size, shape, and density. The machine features an advanced feeding system that carefully portions the meat mixture, while its forming mechanism employs precise pressure control to create meatballs that maintain their shape throughout cooking. The processing capacity typically ranges from 1,000 to 3,000 pieces per hour, depending on the model and size settings. Equipped with stainless steel construction and food-grade components, the machine meets stringent hygiene standards and facilitates easy cleaning and maintenance. The digital control panel allows operators to adjust various parameters including size, density, and production speed, ensuring optimal results for different recipes and production requirements. This versatile equipment is suitable for various environments, from commercial kitchens to large-scale food processing facilities, offering efficient production solutions for restaurants, catering services, and food manufacturers.