Producing protein balls manually can be slow and inconsistent. A protein ball machine transforms this process by automating production. It ensures every piece meets the same quality and size standards. You no longer need to rely heavily on manual labor, which reduces costs and saves time. This machine also eliminates inefficiencies that often limit production speed. By using it, you can scale your business effortlessly while maintaining product consistency. Its precision and reliability make it an essential tool for improving overall efficiency in protein ball manufacturing.

Challenges in traditional protein ball production

Labor-intensive and time-consuming processes

Producing protein balls manually requires significant effort. You need to measure ingredients, mix them thoroughly, and shape each ball by hand. This process takes a lot of time and energy, especially when fulfilling large orders. The repetitive nature of these tasks can also lead to fatigue, which slows down production even further. As demand grows, keeping up with orders becomes increasingly difficult without additional labor. This reliance on manual work limits your ability to produce efficiently.

Inconsistent product quality and size

When making protein balls by hand, achieving consistency is a challenge. Each ball may vary in size, shape, or texture due to human error. These inconsistencies can affect customer satisfaction and harm your brand's reputation. Customers expect uniformity in the Products they purchase. If one batch differs from another, it may lead to complaints or lost business. Maintaining consistent quality is essential, but manual production makes this goal harder to achieve.

Limited scalability for growing businesses

Scaling up production is a major hurdle when relying on traditional methods. As your business grows, you need to meet higher demand without compromising quality. Hiring more workers or extending production hours increases costs significantly. These expenses can strain your budget and reduce profitability. Additionally, manual production methods often lack the speed and efficiency required to handle larger volumes. This limitation prevents you from expanding your operations effectively.

"Traditional production methods often struggle to keep up with growing demand, leading to inefficiencies and missed opportunities."

Switching to automated solutions, like a protein ball machine, can help overcome these challenges. Automation streamlines production, ensures consistency, and supports scalability, making it an essential investment for businesses aiming to grow.

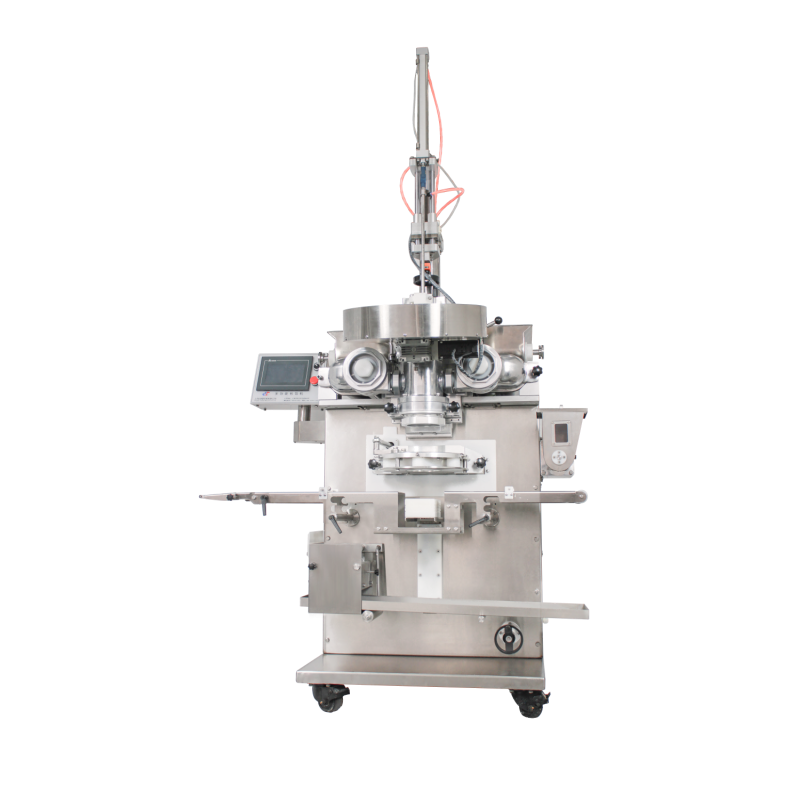

Key features of a protein ball machine that enhance efficiency

Automation for faster production

A protein ball machine automates the entire production process, allowing you to produce more in less time. Manual production often slows down as demand increases, but automation eliminates this bottleneck. The machine handles tasks like mixing, portioning, and shaping with precision and speed. You can produce up to 40 protein balls per minute, which significantly boosts your output. This efficiency helps you meet customer demands without delays or overworking your team. Automation also reduces repetitive tasks, freeing up your time to focus on other aspects of your business.

Precision in portioning and shaping

Achieving uniformity in size and shape is crucial for maintaining product quality. A protein ball machine ensures every protein ball meets the same standards. It uses advanced technology to portion ingredients accurately and shape them consistently. This precision minimizes waste and ensures that each product looks professional. Customers notice and appreciate consistency, which builds trust in your brand. By using the machine, you eliminate the guesswork and human error that often occur in manual production.

Adjustable parameters for recipe flexibility

Flexibility is essential when creating products that cater to different tastes and dietary needs. A protein ball machine allows you to adjust parameters like size, filling amount, and texture. This feature lets you experiment with new recipes or customize products for specific customer preferences. You can easily switch between different types of protein balls without disrupting the production process. This adaptability helps you stay competitive in a market where variety and innovation are key to success.

Easy-to-clean and maintain design

Keeping your equipment clean is essential for maintaining food safety and ensuring smooth operations. A protein ball machine features a design that simplifies cleaning and maintenance. Its components are often detachable, allowing you to disassemble the machine quickly. This feature makes it easier to access hard-to-reach areas where residue might accumulate. You can clean these parts thoroughly without spending excessive time or effort.

The materials used in the machine are typically food-grade and resistant to corrosion. These qualities ensure durability and hygiene. Smooth surfaces prevent food particles from sticking, reducing the risk of contamination. By maintaining a clean machine, you also extend its lifespan and avoid unexpected breakdowns.

Routine maintenance becomes less of a hassle with this user-friendly design. Clear instructions and accessible parts make it simple to perform regular checks. You can replace worn-out components or lubricate moving parts without professional assistance. This ease of maintenance minimizes downtime and keeps your production running efficiently.

An easy-to-clean and maintain design not only saves time but also ensures compliance with food safety standards. It allows you to focus more on production and less on upkeep. This feature makes the protein ball machine a practical and reliable choice for your business.

Measurable benefits of using a protein ball machine

Reduced labor costs and reliance on manual work

Using a protein ball machine significantly lowers your labor expenses. Manual production requires hiring more workers to meet growing demand, which increases costs. With automation, you can reduce the number of employees needed for repetitive tasks like mixing, portioning, and shaping. The machine handles these processes efficiently, allowing your team to focus on other critical areas of your business, such as marketing or customer service.

By minimizing reliance on manual work, you also reduce the risk of errors caused by fatigue or inexperience. This improvement leads to fewer mistakes, saving you money on wasted materials. Over time, the cost savings from reduced labor and waste make the machine a cost-effective investment for your business.

Increased production speed and output

A protein ball machine dramatically boosts your production speed. While manual methods limit how quickly you can produce, the machine operates at a consistent pace. It can produce up to 40 protein balls per minute, enabling you to fulfill large orders without delays. This efficiency ensures that you meet customer expectations, even during peak demand periods.

Faster production also allows you to take on more orders, increasing your overall output. You can expand your customer base and grow your business without worrying About production bottlenecks. The machine’s ability to maintain high-speed operations ensures that you stay competitive in a fast-paced market.

Improved product consistency and quality

Consistency is crucial for building trust with your customers. A protein ball machine ensures that every product meets the same size, shape, and quality standards. This uniformity enhances your brand’s reputation and keeps customers satisfied. They know they can rely on your products to deliver the same experience every time.

The machine’s precision reduces the likelihood of errors, such as uneven portioning or misshapen products. It also minimizes waste by using ingredients efficiently. Improved consistency and reduced waste contribute to higher profitability and better customer retention. By maintaining high-quality standards, you position your business as a reliable choice in the market.

"Investing in a protein ball machine not only improves efficiency but also ensures that your products consistently meet customer expectations."

Enhanced scalability for business growth

A protein ball machine empowers your business to scale production effortlessly. As demand increases, manual methods often struggle to keep up. The machine eliminates this bottleneck by delivering consistent performance, even during peak production periods. You can handle larger orders without compromising quality or overburdening your team.

Expanding your product line becomes more manageable with this technology. The machine’s adjustable settings allow you to create various protein ball types, catering to diverse customer preferences. This flexibility helps you attract a broader audience and meet market demands effectively.

Investing in automation also reduces the need for additional labor as your business grows. Instead of hiring more workers, you can rely on the machine to maintain high output levels. This approach lowers operational costs and increases profitability. It ensures that your business remains competitive while scaling operations.

The machine’s efficiency supports long-term growth. By producing more in less time, you can explore new markets and partnerships. Meeting higher demand becomes achievable without sacrificing the consistency that customers expect. This scalability positions your business for sustained success in a competitive industry.

"Automation is the key to unlocking growth potential, enabling businesses to scale efficiently while maintaining quality."

Real-world examples of improved efficiency

Case study: A small business scaling up production

Imagine running a small protein snack business. You start with a few orders from local customers, but word spreads quickly. Soon, demand grows beyond what your team can handle manually. This was the challenge faced by a small business owner who decided to invest in a protein ball machine.

Before automation, the team spent hours measuring, mixing, and shaping each protein ball by hand. The process was slow and exhausting. Meeting larger orders required hiring temporary workers, which increased costs and reduced profit margins. Despite their best efforts, inconsistencies in size and shape often led to customer complaints.

After introducing the protein ball machine, production transformed. The machine automated the entire process, producing up to 40 protein balls per minute. This speed allowed the business to fulfill larger orders without delays. The machine’s precision ensured that every protein ball met the same quality standards, improving customer satisfaction.

The owner also noticed significant cost savings. Fewer workers were needed for production, which reduced labor expenses. The team could now focus on marketing and expanding the product line. Within months, the business scaled up operations and started supplying to regional retailers. The protein ball machine became the key to their growth and success.

Case study: A large manufacturer reducing costs and waste

A large-scale protein snack manufacturer faced a different challenge. Their manual production methods created inefficiencies that led to high operational costs and excessive waste. Despite having a skilled workforce, maintaining consistency across thousands of protein balls was nearly impossible. Variations in size and shape resulted in wasted materials and dissatisfied clients.

To address these issues, the company integrated a protein ball machine into their production line. The results were immediate and measurable. The machine’s precision eliminated inconsistencies, ensuring that every protein ball met exact specifications. This improvement reduced material waste significantly, saving the company thousands of dollars annually.

The automation also streamlined the workflow. Tasks that once required multiple workers were now handled by the machine. This change allowed the company to reassign employees to other critical areas, such as quality control and logistics. Labor costs decreased, and overall efficiency improved.

With the protein ball machine, the manufacturer could meet higher demand without increasing production costs. They expanded their distribution network and secured contracts with major retailers. The machine not only reduced waste but also positioned the company as a leader in the protein snack industry.

"Real-world examples show how automation can transform businesses, from small startups to large manufacturers, by improving efficiency and reducing costs."

A protein ball machine revolutionizes how you approach production. It eliminates inefficiencies by automating tasks, ensuring precision, and supporting scalability. You can reduce costs, speed up production, and deliver consistent quality with ease. This technology empowers you to meet growing demand without compromising standards. By investing in a protein ball machine, you position your business for long-term success. It’s not just a tool; it’s a strategic asset that enhances efficiency and drives growth.