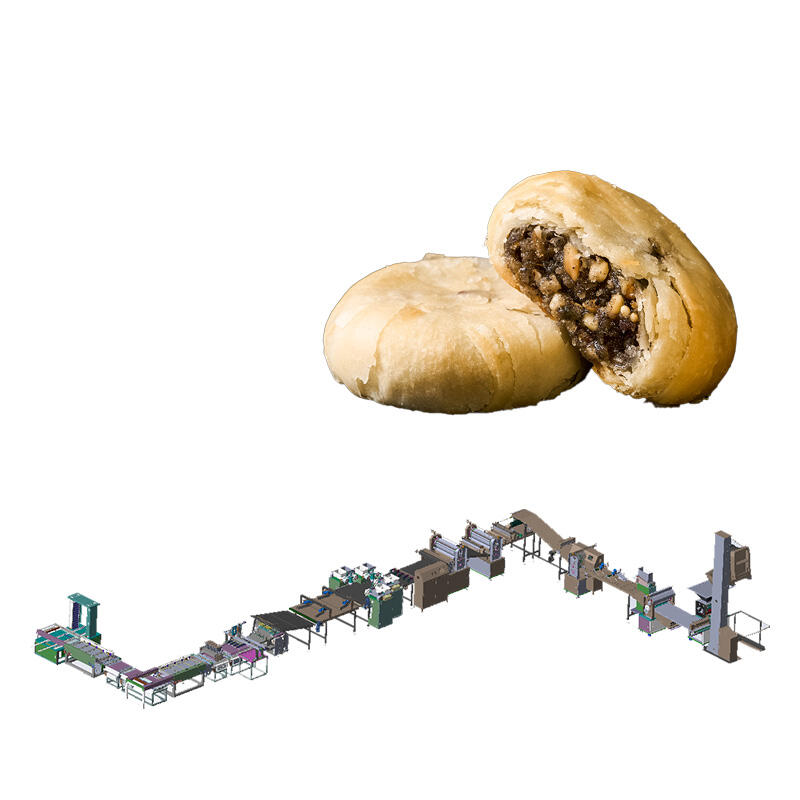

coating machine for date ball

The coating machine for date ball is a sophisticated piece of equipment designed to efficiently coat date balls with a variety of finishes, ensuring an appealing and protective outer layer. The main functions of this machine include precise dosage control, even coating application, and rapid production capabilities. Technological features include an advanced control system that allows for easy operation and customization of the coating process according to different recipes. The machine also boasts a hygienic design with stainless steel construction, which is vital for maintaining food safety standards. In terms of applications, the coating machine for date balls is widely used in the confectionery and snack industries for the production of coated date balls that are both visually attractive and have an extended shelf life.