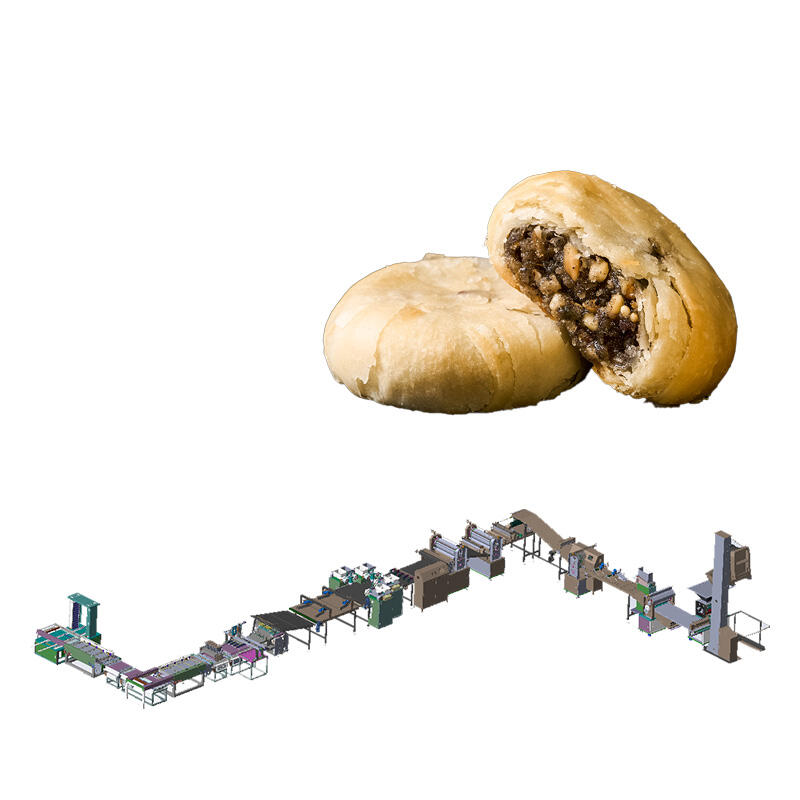

automatic puff pastry making machine

The automatic puff pastry making machine represents a groundbreaking advancement in commercial bakery equipment, designed to streamline the intricate process of creating perfectly layered pastries. This sophisticated piece of machinery automates the entire production process, from dough preparation to the final folding stages. The machine features precise temperature control systems that maintain optimal conditions for dough handling, ensuring consistent quality throughout production. Its advanced rolling mechanism creates uniform dough sheets while incorporating butter layers with remarkable precision, eliminating the need for manual lamination. The machine's programmable interface allows operators to adjust settings for different pastry types, including croissants, Danish pastries, and traditional puff pastries. With production capabilities ranging from 100 to 500 kg per hour, it caters to various business scales. The integrated sheet folding system performs multiple folds automatically, creating the signature flaky layers that characterize perfect puff pastry. Safety features include emergency stop buttons, protective guards, and automated fault detection systems. The machine's stainless steel construction ensures durability and meets strict hygiene standards, while its modular design facilitates easy cleaning and maintenance.