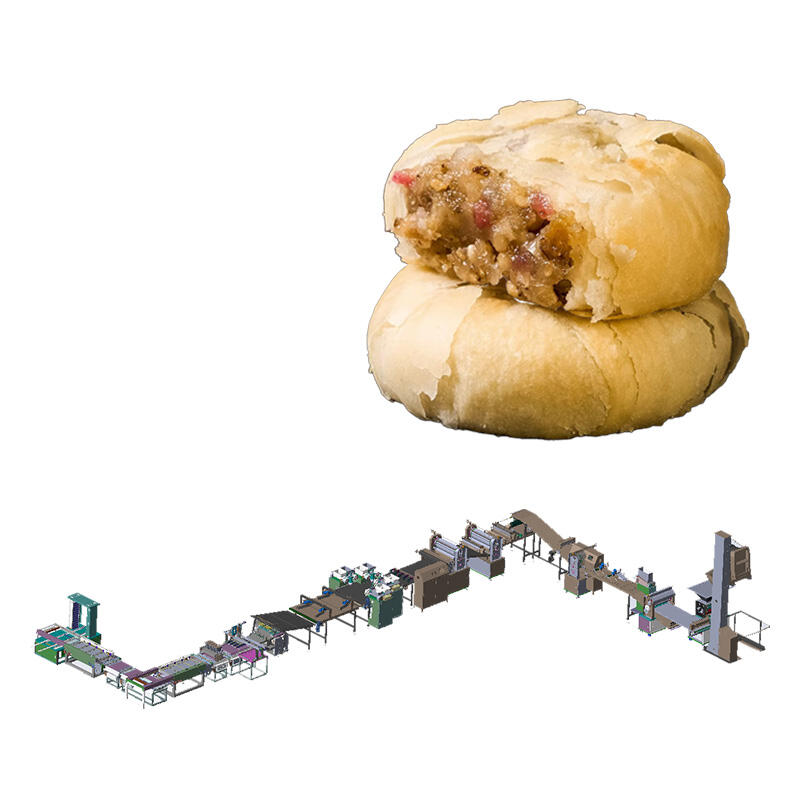

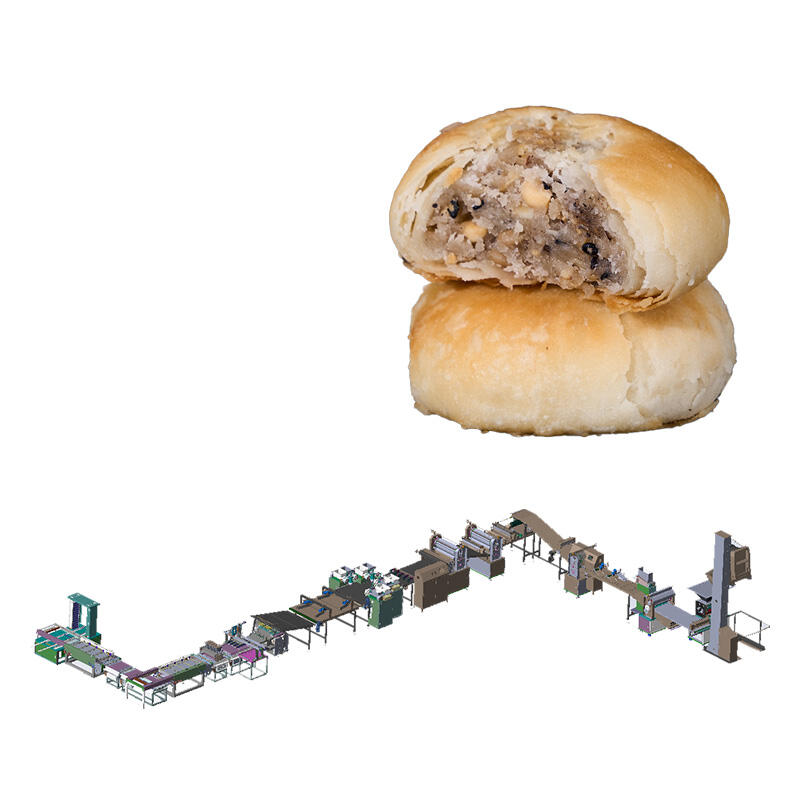

bakery products manufacturing machinery

Bakery products manufacturing machinery represents a comprehensive suite of equipment designed to streamline and automate the production of various baked goods. These sophisticated systems integrate multiple components including mixers, dough dividers, rounders, proofers, and ovens, working in harmony to ensure consistent quality and high production efficiency. The machinery employs advanced technological features such as programmable logic controllers (PLCs), touch-screen interfaces, and precision temperature control systems to maintain optimal baking conditions. Modern bakery equipment incorporates sanitary design principles, featuring stainless steel construction and tool-less disassembly for thorough cleaning. The machinery can handle diverse product requirements, from artisanal bread to mass-produced pastries, with automated systems for ingredient dispensing, dough handling, and packaging. Energy-efficient features include heat recovery systems and intelligent power management, while integrated quality control mechanisms ensure product consistency. These systems can be scaled to meet various production volumes, from medium-sized bakeries to industrial-scale operations, offering flexibility in output capacity and product variety.