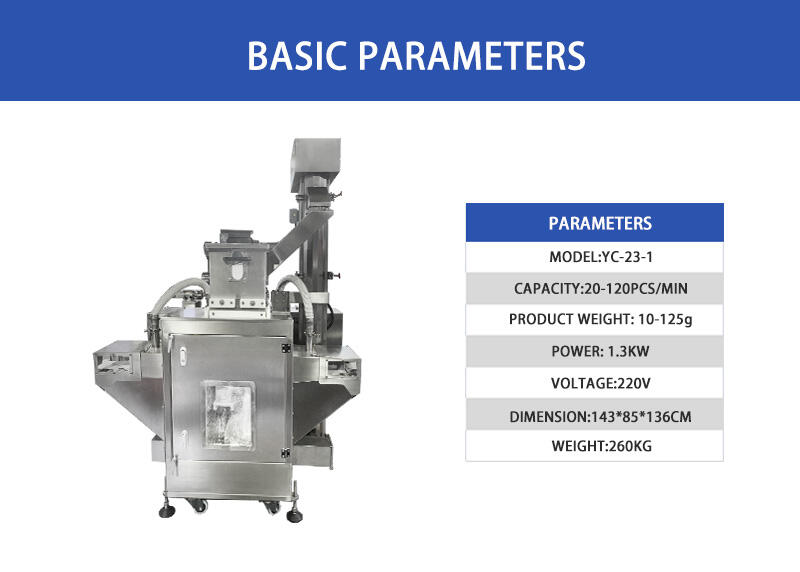

center filled date bar machine

The center filled date bar machine represents a sophisticated piece of food processing equipment designed specifically for manufacturing date-based confectionery products with various filling options. This advanced machinery combines precision engineering with automated processing capabilities to create uniform, high-quality date bars with consistent center filling. The machine features a series of integrated components, including a date paste preparation system, filling injection mechanism, and precise temperature control units. It processes dates through multiple stages, first creating a uniform outer layer of date paste, then accurately injecting the desired filling into the center, before forming and cutting the product into standardized bars. The system maintains optimal temperature conditions throughout the process to ensure proper consistency and texture. With production capacities ranging from 100 to 500 kg per hour, depending on the model, these machines cater to both medium and large-scale manufacturing operations. The equipment incorporates safety features such as emergency stop mechanisms, sanitary grade stainless steel construction, and easy-clean designs that comply with food safety regulations. Advanced control systems allow operators to adjust parameters including filling ratios, bar dimensions, and production speed, ensuring versatility in product specifications.