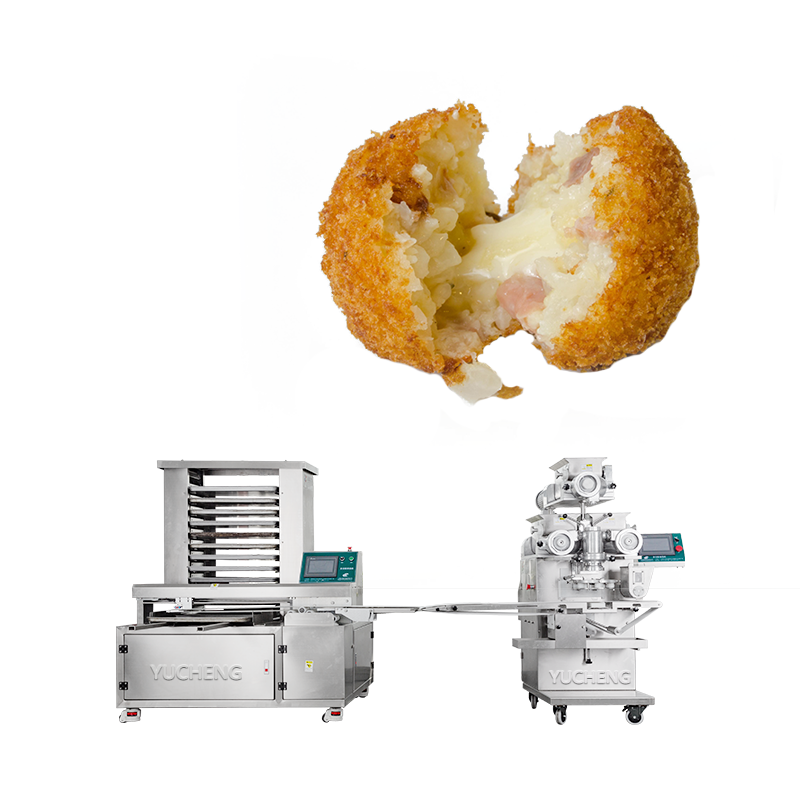

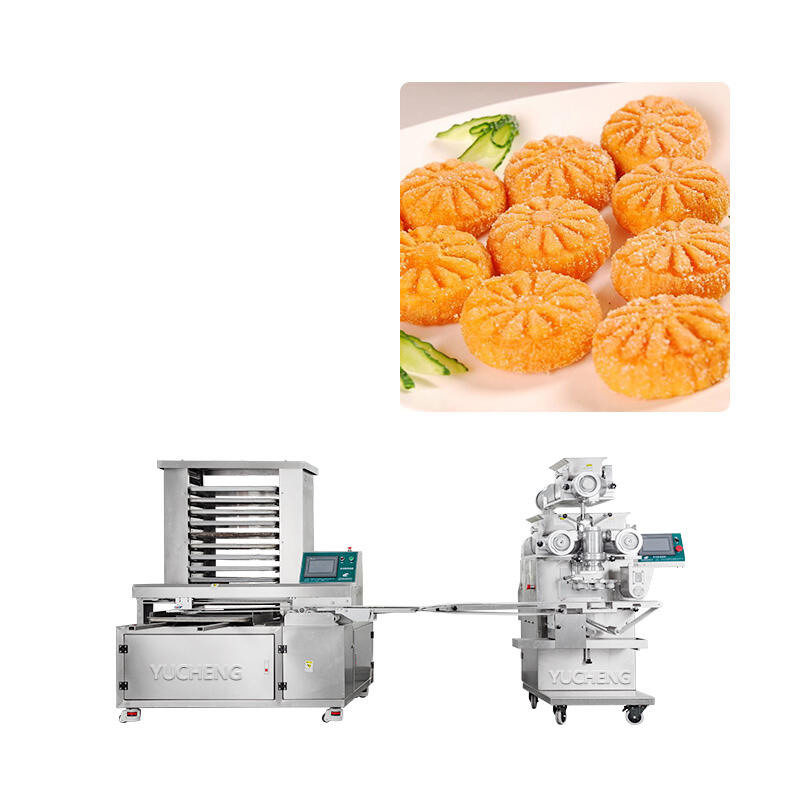

kubba making machine

The kubba making machine represents a groundbreaking advancement in Middle Eastern cuisine automation, designed to streamline the production of traditional kubba, a beloved stuffed dumpling dish. This innovative equipment combines precision engineering with user-friendly operation to transform the labor-intensive process of kubba making into an efficient, consistent production line. The machine features a sophisticated dough-forming mechanism that creates perfectly proportioned outer shells while maintaining the authentic texture that characterizes traditional kubba. Its dual-chamber system allows for simultaneous preparation of the outer shell and filling components, significantly reducing production time. The machine's automated portioning system ensures uniform size and shape for every piece, maintaining quality consistency across large batches. With adjustable settings for dough thickness and filling quantity, it accommodates various kubba styles and regional preferences. The stainless steel construction ensures durability and compliance with food safety standards, while the intuitive control panel enables operators to easily adjust parameters and monitor production. This machine can produce up to 1,200 pieces per hour, making it ideal for restaurants, catering services, and food manufacturing facilities looking to scale their kubba production efficiently.