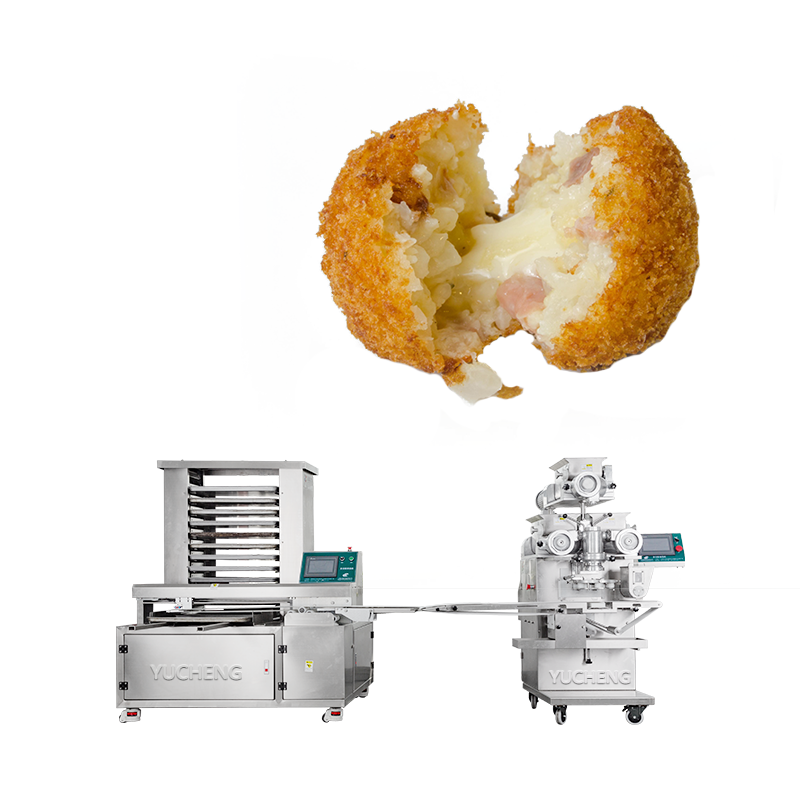

mesin membuat kroket

Mesin pembuat kroket adalah peralatan pengolahan makanan canggih yang dirancang untuk menyederhanakan produksi kroket berkualitas tinggi yang seragam. Mesin serbaguna ini mengintegrasikan berbagai fungsi termasuk pencampuran, pembentukan, dan kemampuan pemotongan, memungkinkan produksi massal efisien dari berbagai jenis kroket. Sistem ini dilengkapi dengan komponen teknologi canggih seperti panel kontrol presisi, pengaturan kecepatan yang dapat disesuaikan, dan lampiran cetakan yang dapat dipersonalisasi untuk menampung berbagai bentuk dan ukuran. Konstruksi baja tahan karat mesin ini memastikan ketahanan dan kepatuhan terhadap standar keamanan pangan, sementara operasi otomatisnya secara signifikan mengurangi kebutuhan tenaga kerja manual. Dengan kapasitas produksi berkisar dari 1.000 hingga 3.000 potong per jam, cocok untuk produsen makanan berskala menengah dan operasi industri besar. Mesin ini mencakup fitur inovatif seperti ruang pencampuran dengan kontrol suhu untuk menjaga konsistensi bahan optimal dan sistem pemotongan otomatis untuk memastikan distribusi ukuran dan berat yang seragam. Antarmuka pengguna yang ramah memungkinkan operator dengan mudah menyesuaikan parameter seperti waktu pencampuran, ukuran porsi, dan tekanan pembentukan, membuatnya dapat diadaptasi ke berbagai resep dan persyaratan produksi.