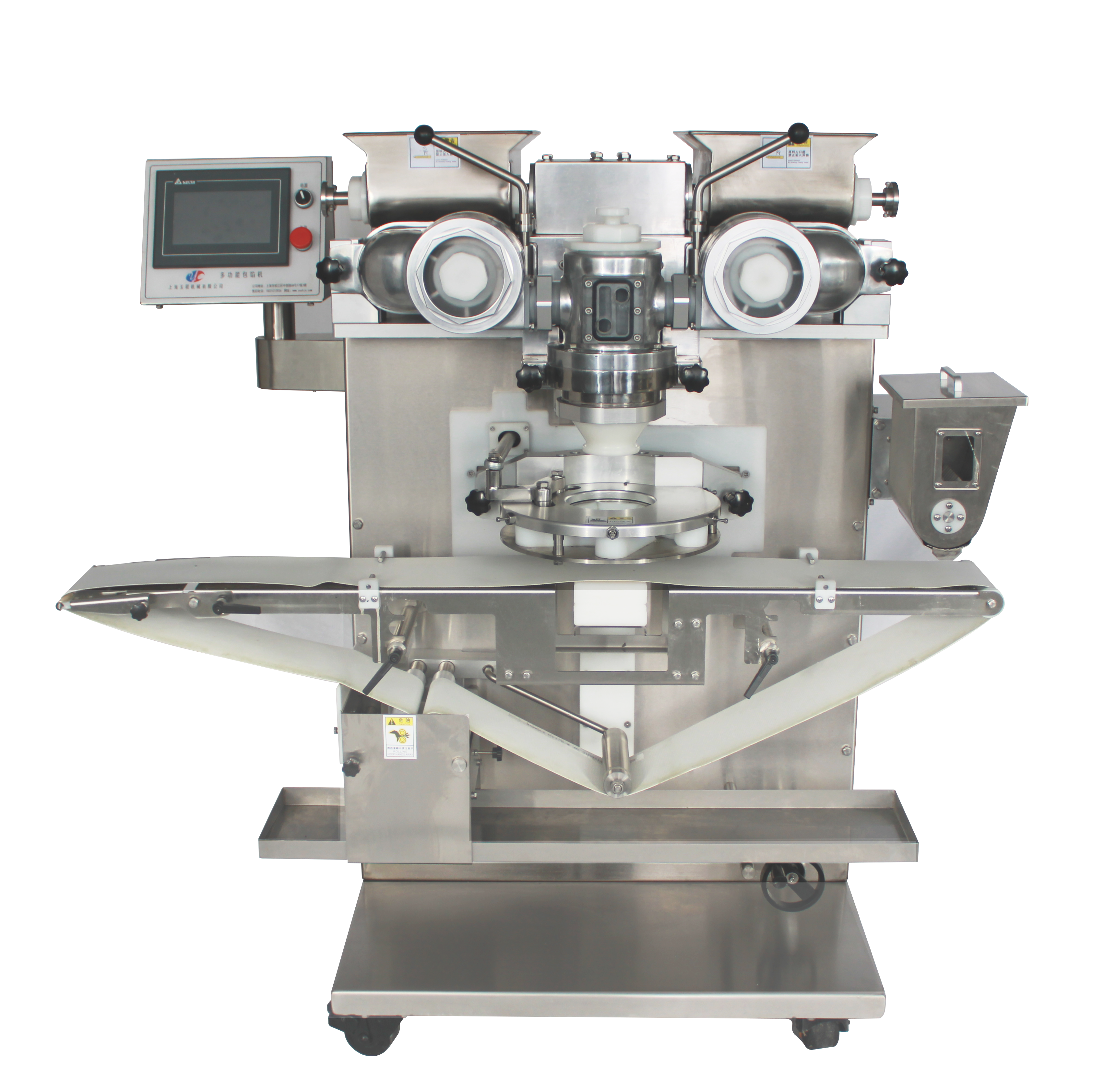

machine for date bar

The machine for date bar production represents a significant advancement in food processing technology, designed specifically for manufacturing high-quality date-based snack products. This sophisticated equipment integrates multiple processing stages into a seamless operation, including date paste preparation, mixing, forming, cutting, and packaging capabilities. The machine features state-of-the-art controls that ensure precise temperature regulation and consistent product quality throughout the production process. With its stainless steel construction and hygienic design, it meets stringent food safety standards while providing optimal performance. The system can process various date varieties and accommodate different recipe formulations, offering flexibility in production. Its automated features include adjustable speed controls, precise portion measurement, and efficient cutting mechanisms that guarantee uniform product dimensions. The machine's modular design allows for easy maintenance and cleaning, while its intelligent control system enables operators to monitor and adjust processing parameters in real-time. With production capacities ranging from small-scale operations to industrial-level output, this equipment can be customized to meet specific manufacturing requirements. The integration of energy-efficient components and waste reduction features makes it an environmentally conscious choice for modern food processing facilities.